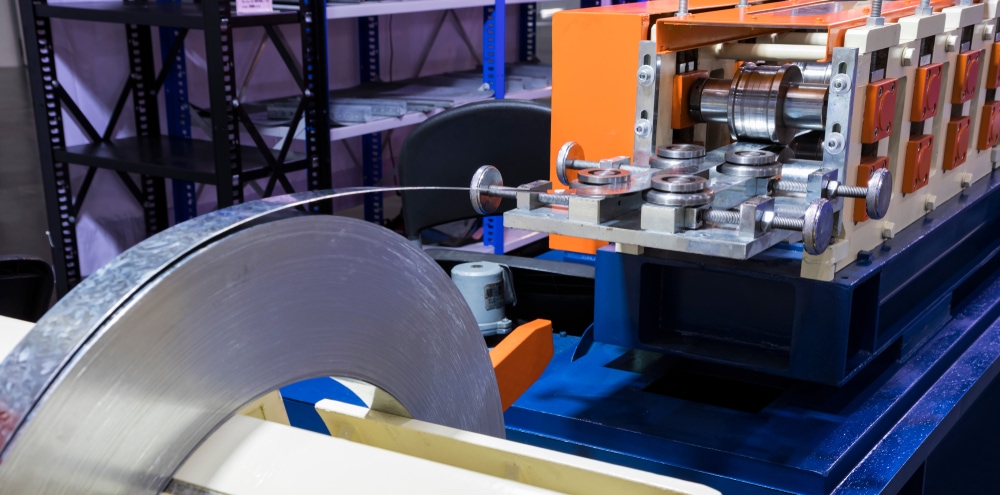

Welcome to the world of metal rolling applications! This process is an integral part of manufacturing for many industries, and it can be used for a wide variety of purposes—from light-gauge sheet rolling to heavy gauge plate forming.

Whether you are new to this fascinating technique or looking for insights from an expert’s perspective, here you will find valuable information about the different types of rollers and how the metal rolling process can be used in various applications. Read on to learn more about how this age-old process remains relevant today!

Types of Rolling

Rolling metal is a specialized process that requires precision, carefulness, and the right equipment. Whether creating custom-fabricated parts or manufacturing something for mass production, having a reliable rolling machine can be highly advantageous in consistently achieving accurate results.

Plate rolling

In plate rolling, metal sheets are rolled into cylindrical items like pipes, buckets, and tanker trailers. With its working mechanism, the rolling machine can bend flat sheet metal into large arcs, cylinders, squares, ellipses, and multi-section arcs.

Plate metal rolling can create thinner and stronger metals and is more precise than other methods, meaning less material is wasted during manufacturing.

Angle rolling

Angle rolling is a process used to shape metal into curved or angular shapes. With this process, sharp edges are removed, strength is improved, and benefits are provided functionally and cosmetically. Angle rolling is often used to create pipes, tubes, and other cylindrical objects. It is a popular method for creating metal furniture and other decorative items.

Beam rolling

Steel beams are bent by beam rolling. Bending strength increases with depth cubed by the depth. Due to this, beams are very stiff. That’s why the web’s thickness mustn’t be too thin to prevent buckling.

In addition, beam rolling gradually reduces the thickness of the ingot until it reaches the desired thickness. It can create beams of any size and shape, making it an extremely versatile process.

Tube rolling

Tube rolling is a process used to create cylindrical tubes from flat metal sheets. The process involves passing the flat sheet of metal through a series of rollers, each of which progressively bends the metal until it takes on the desired shape.

The main advantage of tube metal rolling over other methods of tube fabrication is that it is much faster and more efficient. Additionally, the process can be easily automated, which further increases efficiency.

Custom Metal Rolling Applications

From sizeable industrial performance parts to small custom components, metal rolling can provide various options for companies seeking mass production and one-off solutions. Whether you need a specific component for the latest construction project or an artistic piece as part of a creative build, this process can be tailored to meet your needs.

Military-grade metal parts for land, sea, and air

The ballistic limit test is a special test conducted on military grades. Ballistic testing uses a controlled projectile, firing pattern, and velocity to determine the velocity at which a target will be penetrated entirely and partially.

Typically used in defense applications, MIL-12560 armor absorbs shock exceptionally well, making it a popular military-spec armor. With our iron and aluminum products that are highly sought after for their extreme toughness, lightweight construction, and durability, we ensure you will get the best quality metal parts that are military grade standard.

Custom cyclone setups for the recycling industry

Cyclone separators are used to remove particulates from flue gases. An easy-to-empty container beneath the cyclone collects up to 99% of airborne waste. Our custom metal rolling is perfect for this industry due to its efficient and thorough processing services in collecting plastic particles that will maximize the potential of each component.

Hospital and prison-grade structural components

Paramount Roll & Forming’s commitment to providing quality fabricated steel to hospitals and prisons makes us successful. Our services benefit prisons that use steel for structural components and high-security doors and frames. Meanwhile, we also provide hospitals with metal parts for their steel structural components that limit noise and have vibration control.

We provide a complete service from start to finish, from design to fabrication, ensuring that your vision perfectly meets your specifications. Every step is carefully monitored, inspected, and evaluated to provide a superior outcome.

Our metal rollers utilize computer-guided methods that ensure accuracy and precision – no detail is too small to be overlooked, and every part is customized to meet specific needs and requirements.

Custom Metal Bending from Paramount Roll and Forming

As California’s first pipe roller in 1963 and today, a full-service provider of custom metal fabrication, Paramount Roll and Forming specializes in metal bending and rolling services.

Custom metal assemblies and structures are one of our core specialties – having over six decades of experience in metal bending and can handle virtually any project. We can bend and make channels, plates, tubes, beams, and channels out of aluminum, steel, and other high-performance alloys.

Contact us today to learn more about our custom metal bending services and get started on your next project.